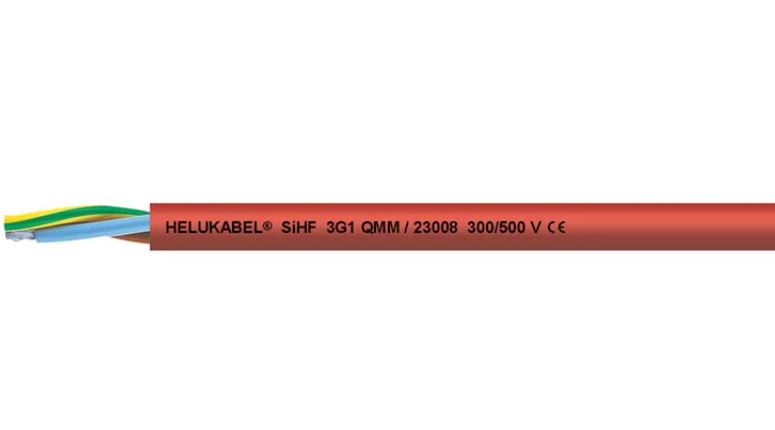

Helukabel SiHF

| Description | Silicone cable increased temperature resistance tinned wire |

| Cable Structure | Copper wire tinned, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5 Core insulation: silicone Core identification acc. to DIN VDE 0293-308, 2 – 5 core(s): colour coded 6 – 25 core(s): black cores with consecutive labeling in white digits Protective conductor: starting with 3 cores, G = with protective conductor GN-YE, in the outer layer, x = without protective conductor Cores stranded in layers with optimal lay lengths Outer sheath: silicone Sheath colour: redbrown Length marking: in metres |

| Test | halogen-free acc. to DIN VDE 0482-754-1 / DIN EN 60754-1 / IEC 60754-1 corrosiveness of combustion gases acc. to DIN VDE 0482-754-2 / DIN EN 60754-2 / IEC 60754-2 flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2 certifications and approvals: EAC |

| Application | Silicone cables were evolved for use wherever insulation is subjected to extreme temperature changes. The good performance of the environmental resistant properties means that silicone cables can be used at temperatures down to -60°C. Silicone cables are halogen-free cables and are especially suited for installation in power stations. They have also found their uses in the steel producing industries, aviation industry, ship building as well as in ceramic, glass and cement factories. Due to elastical characteristic of core insulations, these are used as flexible connection cable |