Showing 37–48 of 174 results

-

| Description |

UV resistant

For outdoor use

Largely oil resistant

For outer diameters larger than 18.00mm, suitable for direct burial

Versatile use in many industries, particularly in machine and plant construction |

| Application |

Used as a connection and control cable in machine tools, assembly lines and conveyor belts, production lines, in plant construction, heating and air-conditioning technology, in smelters and steel mills. Suitable for flexible applications involving medium mechanical stress with free movement, without tensile stress and without forced motion control in dry, damp and wet rooms, as well as outdoors (fixed installation). May not be laid directly in soil (suitable for direct burial starting with an outer diameter of 18.0 mm) or water. |

-

| Temperature Range |

flexing -5 °C to +80 °C

fixed installation -40 °C to +80 °C |

| Nominal Voltage |

UL/CSA 600V

U0/U 300/500 V |

| Test Voltage |

4000 V |

| Breakdown Voltage |

min. 8000 V |

| Minimum Bending Radius |

flexing 7.5x cable ø

fixed installation 4x cable ø |

| Cable Structure |

Bare copper conductor, fine wire stranded according to DIN VDE 0295 cl. 5, BS 6360cl. 5 or IEC 60228 cl. 5

Special PVC conductor insulation TI2 according to DIN VDE 0281 Part 1

Black conductors with sequential white numbering in accordance with DIN VDE 0293 Green-yellow ground in the outer layer, 3 cores and more

Conductors stranded in layers with optimal lay-lengths

Outer jacket from special full polyurethaneTMPU according to DIN EN 50363-10-2 With meter marking |

-

| Technical Data |

Special rubber cable adapted to DIN VDE 0250 |

| Temperature Range |

flexing -25°C to +60°C fixed installation -40°C to +80°C |

| Nominal Voltage |

U0/U 300/500 V |

| Test Voltage |

3000 V |

| Minimum Bending Radius |

for continuous bending without forced guiding operation 12,5x cable Ø

for flexing with forced guiding operation 20x cable Ø |

|

-

| Technical Data |

Rubber sheath cable to DIN VDE 0250 part 812 |

| Temperature Range |

flexing -25°C to +80°C

fixed installation -40°C to +80°C

● Resistant against hot penetration

● Core insulation of rubber (EPR)

compound type 3GI3 to

DIN VDE 0207 part 20

● Low abrasion

● High notch resistant

● Permissible operating temperature

at conductor +90°C |

| Nominal Voltage |

U0/U 0,6/1 kV |

| Test Voltage |

3000 V |

| Minimum Bending Radius |

fixed installation 4x cable Ø

flexing 10x cable Ø

without forced operation 15x cable Ø |

|

| Cable Structure |

Tinned copper-conductor, to

DIN VDE 0295 cl.5, fine-wire,

BS 6360 cl.5, IEC 60228 cl.5

Core insulation of rubber (EPR)

compound type 3GI3 to DIN VDE 0207 part 20

Core identification to DIN VDE 0293-308

– up to 5 cores coloured

– from 6 cores, black with continuous white numbering

GN-YE conductor, 3 cores and above

Cores stranded in layers with optimal lay-length |

|

|

|

|

|

|

| Test |

Behaviour in fire to DIN VDE 0482-332-1-2 DIN EN 60332-2-1, IEC 60332-1 (equivalent

DIN VDE 0472 part 804 test method B) Oil resistant to DIN EN 60811-404 |

-

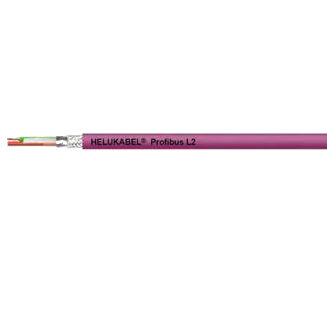

| Description |

Profibus acc. to DIN 19245 T3 and EN50170 Flame-retardant acc. IEC 60332-2-1 |

| Cable Structure |

Inner conductor diameter: Copper, bare (AWG 24/7)

Core insulation: Foam-skin-PE

Core colours: rd, gn

Stranding element: 2 cores + 2 fillers stranded together

Separator: Polyester foil over stranded bundle

Shielding 1: Al-Foil

Total shielding: Cu braid, tinned

Outer sheath material: PVC

Cable external diameter: app. 7,8 mm ± 0,3 mm

Outer sheath colour: Violet similar to RAL 4001 |

| Test |

Test voltage: 1,5 kV Attenuation: dB/km 9,6 kHz < 2,9 38,4 kHz < 4,6 dB/km 4 MHz < 25,0 dB/km 16 MHz < 49,0 dB/km |

| Application |

Profibus L2 7-wire for mobile applications in Profibus industrial networks. With its core design and the special PVC sheath, the type

described here is suitable for normal mobile applications. |

|

|

-

| Temperature Range |

flexible +5°C to +70°C fixed -30°C to +80°C |

| Nominal Voltage |

AC U0/U 450/750 V |

| Test Voltage |

2500 V |

| Minimum Bending Radius |

fixed |

|

<8 mm: 4x Outer-ø |

|

8-12 mm: 5x Outer-ø |

|

>12 mm: 6x Outer-ø |

| Cable Structure |

Copper wire bare, finely stranded acc. to DIN VDE 0295 Class 5 /

IEC 60228 Class 5

Core insulation: PVC acc. to DIN VDE 0207-363-3 /

DIN EN 50363-3 (compound type TI1) |

-

| Description |

Computer cable

reinforced outer sheath

with drain wire

Suitable for outdoor use (for fixed installations)

with blue outer sheathing: for intrinsically safe systems in explosion-endangered areas |

| Cable Structure |

Copper wire bare, stranded

Wire structure:

0.5 mm²: 7 x 0.3 mm

0.75 mm²: 7 x 0.37 mm

1.3 mm²: 7 x 0.49 mm

Core insulation: PE

Core identification: colour coded, pairs:

a-core = black; b-core = white

with consecutive numbering 1/1, 2/2, etc.,

triads: a-core = black; b-core = white; c-core = red

Cores stranded in pairs / triads with optimal lay lengths, Pairs stranded in layers with optimal lay lengths

for multiple pair design: communication core, nominal cross-section: 0.5 mm², Core insulation: PE, Core identification: orange

Foil wrapping

Drain wire, tinned copper, stranded (0.5 mm² = 7 x 0.3 mm)

Screen: plastic-coated aluminium foil (St), approx. overlap 25%

Outer sheath: PVC, reinforced (v)

Sheath colour: see datasheet

Length marking: in metres |

| Test |

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

certifications and approvals:

EAC |

| Application |

Instrumentation cables are used in data processing and process control. Low level of line attenuations and low mutual capacitances enable long transmission distances and fast pulse acceleration. Instrumentation cables are suitable for fixed installations in damp locations, in open spaces and for underground laying. |

|

|

-

| Description |

Silicone single core

finely stranded

tinned wire

increased temperature resistance |

| Cable Structure |

Copper wire tinned, finely stranded, 0.5 – 185 mm²: acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

Wire structure:

0.25 mm²: approx. 8 x 0.2 mm

Core insulation: silicone

Core identification: see datasheet |

| Test |

halogen-free acc. to DIN VDE 0482-754-1 / DIN EN 60754-1 / IEC 60754-1

corrosiveness of combustion gases acc. to DIN VDE 0482-754-2 / DIN EN 60754-2 / IEC 60754-2

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

certifications and approvals:

EAC |

| Application |

Temperature resistant silicone single core for use in iron, steel and rolling mills, foundries, cement, glass and ceramic factories as well as in aircraft construction and ship building. |

|

|

-

| Description |

Spezial-silicon single core with higher heat-resistance range adapted to DIN VDE 0250 Teil 1 and part 502 |

| Cable Structure |

Tinned copper-conductor, from 0,5 mm² to

DIN VDE 0295 cl.5, fine-wire, BS 6360 cl.5, IEC 60228 cl.5 Conductor construction: 0,25 mm² = 14×0,15mm Core insulation of silicone Glass-fibre braiding |

| Test |

Corrosiveness of combustion gases (Halogen-free) acc. to DIN VDE 0482 part 267, DIN EN 50267-2-2, IEC 60754-2 (equivalent DIN VDE 0472 part 813) Behaviour in fire no flame propagation acc. to DIN VDE 0482-332-1-2, DIN EN 60332-1-2,IEC 60332-1 (equivalent

DIN VDE 0472 part 804 test method B) |

| Application |

Special single cores for use in high, resp. low temperature areas. They are used mainly in the steel producing industries, in aviation industries as well

as in ship building, cement, glas and ceramic factories. As this single cores are halogen-free, especially suited for use in power stations.

= The product is conformed with the EC Low-Voltage Directive 2006/95/EC. |

|

|

-

| Description |

Silicone cable

increased temperature resistance

tinned wire |

| Cable Structure |

Copper wire tinned, finely stranded acc. to DIN VDE 0295 Class 5 / IEC 60228 Class 5

Core insulation: silicone

Core identification acc. to DIN VDE 0293-308,

2 – 5 core(s): colour coded

6 – 25 core(s): black cores with consecutive labeling in white digits

Protective conductor: starting with 3 cores,

G = with protective conductor GN-YE, in the outer layer,

x = without protective conductor

Cores stranded in layers with optimal lay lengths

Outer sheath: silicone

Sheath colour: redbrown

Length marking: in metres |

| Test |

halogen-free acc. to DIN VDE 0482-754-1 / DIN EN 60754-1 / IEC 60754-1

corrosiveness of combustion gases acc. to DIN VDE 0482-754-2 / DIN EN 60754-2 / IEC 60754-2

flame-retardant acc. to DIN VDE 0482-332-1-2 / DIN EN 60332-1-2 / IEC 60332-1-2

certifications and approvals:

EAC |

| Application |

Silicone cables were evolved for use wherever insulation is subjected to extreme temperature changes. The good performance of the environmental resistant properties means that silicone cables can be used at temperatures down to -60°C. Silicone cables are halogen-free cables and are especially suited for installation in power stations. They have also found their uses in the steel producing industries, aviation industry, ship building as well as in ceramic, glass and cement factories. Due to elastical characteristic of core insulations, these are used as flexible connection cable |

|

|

-

Cross-linked single core cable acc. to DIN VDE 0283-618 / DINEN 50618

| Temperature Range |

– 40 °C to +90 °C

Max.Temp. at conductor +120 °C |

| Nominal Voltage |

According to VDE 600/1000 V AC

1800 V DC conductor/conductor |

| AC Test Voltage |

10000 V |

| Minimum Bending Radius |

for continuous bending without forced guiding operation 12,5x cable Ø

for flexing with forced guiding operation 20x cable Ø |

|

-

| Description |

largely oil resistant

transparent outer sheath

with PVC inner sheath

galvanised steel wire braid to protect against mechanical damages

versatile use in many industries, particularly in machine and plant construction |